Enhancing Cargo Security and Preventing Load Shifting

How E Track Accessories Stabilize Cargo in Trailers and Vans

E Track accessories offer a pretty solid way to stabilize cargo since they attach directly to those reinforced steel rails inside trailers and vans. The anchor points can hold around 2000 pounds each, and there are adjustable straps plus hooks that work well for oddly shaped items too. Take sliding furniture or heavy machinery as an example these get locked down nicely with dual sided E Track rails combined with ratchet straps. This setup really cuts down on side to side movement when the vehicle makes sudden stops. According to some recent research from cargo securement studies back in 2023, this system actually reduces wear caused by friction by about 42 percent compared to old school tie down methods.

Role of E-Track Ratchet and Cam Straps in Secure Transit

The E-track ratchet straps spread out tension evenly across the load, which is really important when trying to keep heavy or uneven stuff stable during transport. For lighter cargo, cam straps work great too since they snap on quickly and have this 6 to 1 grip ratio that stops things from sliding around even on hills. Pairing either type with D-ring anchors helps keep everything tight while moving, so there's less chance of stuff shifting when the truck hits the brakes hard or takes a sharp corner. According to some industry stats we saw last year, companies that switch to standard E-track setups report about two thirds fewer problems with loads shifting around during delivery runs.

Case Study: Reducing In-Transit Damage with E-Track Securement Systems

A mid-sized logistics firm reduced cargo damage claims by 57% after retrofitting 120 trailers with E-track accessories. Over six months, the company observed significant improvements:

| Metric | Pre-Installation | Post-Installation |

|---|---|---|

| Average load shift | 3.2 incidents | 0.7 incidents |

| Transit damage rate | 8.5% | 3.6% |

These results reflect broader industry trends showing that proper securement systems can reduce insurance premiums by up to $18,000 annually for fleets. The modularity of E-track rails also enabled 24% faster load adjustments compared to fixed anchor systems.

Minimizing Cargo Damage Through Proper Load Securement

The Impact of Improper Tie-Downs on Cargo Integrity

Shifting loads account for 26% of cargo damage claims (FMCSA 2022), with poorly secured freight accelerating wear on both goods and trailer interiors. Transit vibrations amplify minor movements, increasing friction that degrades packaging and product surfaces over time.

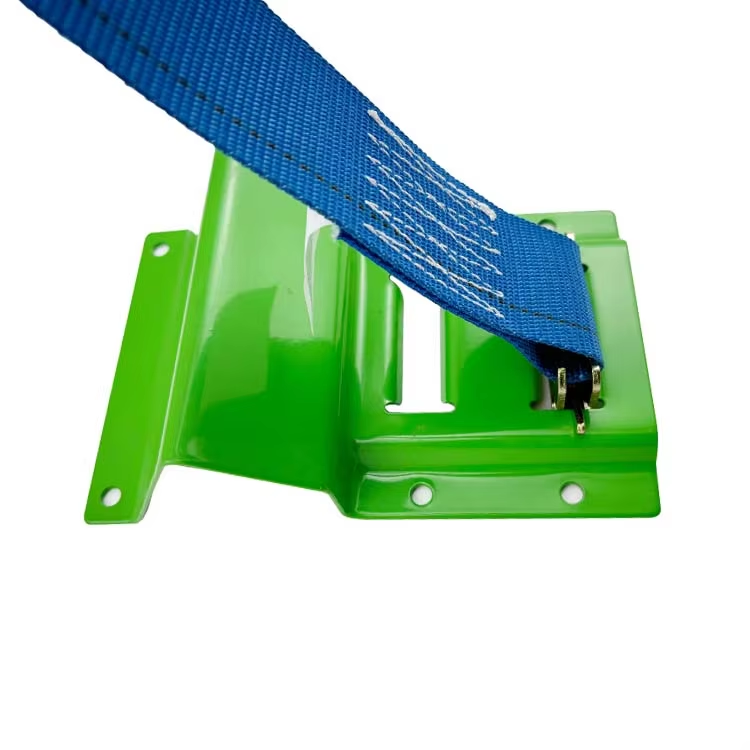

Using E Track Straps, Anchors, and D-Rings for Optimal Protection

E track accessories distribute forces across multiple directions through their interlocking design. When paired with ratcheting cargo straps, these systems maintain tension within ±5% of initial settings—critical for sensitive shipments like electronics or unevenly weighted machinery. Key protective features include:

- 10,000-lb rated D-rings that prevent anchor point failures

- Abrasion-resistant strap coatings that extend equipment life

- Slide-resistant buckles tested to withstand 7G forces (DOT standards)

This comprehensive protection delivers measurable returns: every $1 invested in E-track securement yields $3.80 in reduced claims and operational savings over three years (Transportation Safety Board 2023).

Data Insight: Lower Insurance Claims After E-Track Implementation

A 2023 study of 48 logistics companies found a 41% average reduction in cargo damage claims following adoption of standardized E-track systems. One fleet utilizing vertical rail configurations reduced load-related insurance premiums by $18,200 annually while improving trailer utilization by 19%.

Maximizing Trailer Space and Load Efficiency

Modular E-Track Rail Configurations for Smarter Space Utilization

E Track accessories let users stack vertically by installing adjustable rails that transform otherwise useless trailer walls into actual mounting spots. With this modular setup, storage becomes layered instead of flat, which means most people can get their hands on around 87% of the vertical space inside trailers these days. A recent study from the freight industry in 2024 backs this up. What's really nice is how versatile the system works for all sorts of cargo. Think about those weird shaped tools or machinery versus regular old pallets. There's still enough room between things for workers to load stuff safely without bumping heads or damaging goods. The system keeps about six to eight inches of clearance throughout, making sure everything fits properly without causing accidents during loading and unloading.

Adjustable Attachment Points to Increase Hauling Capacity

Fixed anchor systems are pretty limiting when it comes to adjusting where things get tied down. But with E-Track's sliding D-rings and those handy track clamps, crews can move tie-down points around in less than 90 seconds flat. This kind of flexibility makes all the difference for loading operations. Fleet managers tell us about 5 out of every 10 trucks on the road now report being able to squeeze in anywhere from 12 to 15 percent extra cargo per trip because of this feature. And let's not forget about weight distribution either. The way E-Track spreads out the load means operators can actually max out their trailers at the standard 45,000 pound capacity without worrying about putting unnecessary stress on the frame.

Case Study: 23% Improvement in Trailer Space Efficiency

One regional logistics firm based in Ohio saved around $218k each year once they installed E-Track systems on their fleet of 42 semi-trailers. When they combined wall mounted racks with those special ceiling tracks, their cargo loading efficiency jumped significantly - going from an average of just under 15 pounds per cubic foot to nearly 18 pounds per cubic foot. They managed to cut down on wasted space inside the trailers by almost 40 percent without compromising safety standards for road inspections. A recent study conducted at Purdue back in 2023 confirmed these findings, showing how such modifications can make real money while still meeting all regulatory requirements for commercial transportation.

Enabling Versatile and Customizable Cargo Solutions

Flexible Mounting Options: Horizontal, Vertical, and Cross-Mounted Rails

The E track system works with various rail setups, making it really adaptable for different situations. When mounted horizontally on walls, it helps stack boxes vertically without taking up floor space. Vertical installation close to loading doors gives easy access to things that get moved around often during deliveries. Handling heavier stuff like machines or mixed pallets becomes easier with cross-mounted rails that form stable triangles, keeping everything from sliding sideways during transport. Carriers can adjust their trailer setup pretty quickly when needed, usually within about 15 minutes depending on what they need to carry each trip.

Tailoring E Track Accessories to Specific Cargo and Fleet Needs

When managing their fleet, truck operators put together various track compatible items like adjustable straps, those handy locking D rings, and sliding load bars to handle whatever transportation needs come their way. For transporting temperature sensitive meds, they might need insulated rail covers along with anchors that resist moisture. On the other hand, when hauling auto parts, most go for heavy duty ratchet straps that can take on 10,000 pounds without breaking a sweat. According to a recent 2023 industry poll, around two thirds of companies switching to E track systems saw their equipment expenses drop significantly after ditching several different cargo control methods in favor of just one flexible solution.

Trend Analysis: Rising Demand for Adaptability in Mixed-Freight Transport

Since 2021, there's been about a 40% jump in need for cargo systems that can be rearranged on the fly, as reported by folks in the logistics business. Delivery companies moving everything from fresh fruits to heavy machinery are increasingly going for those E-track attachments that let them swap between cold storage straps for veggies and sturdy anchors for building materials all during one run. What's interesting is how this matches up with what's happening in warehouses too. Around half (about 53%) of third party logistics firms want their trucking partners to stick with standard track systems throughout their operations these days.

Reducing Operational Time and Long-Term Costs

Faster Loading and Unloading with Easy-to-Install E Track Accessories

E track accessories streamline cargo handling with tool-free installation and modular components. Ratchet straps equipped with integrated track hooks secure loads 40% faster than conventional tie-down methods, reducing pre-transit labor while ensuring compliance with DOT standards.

Measurable Time Savings Before and After E-Track Adoption

Fleets report cutting loading-phase time by 18–22 minutes per trailer after replacing chain binders with E-track compatible systems. For high-frequency transporters, this translates to over 50 hours saved annually per vehicle.

Cost Benefits of Durable, Reusable E Track Securement Systems

Commercial-grade steel anchors and UV-resistant straps typically last 5–7 years under daily use, eliminating the recurring expense of disposable tie-downs. A 2024 freight logistics study found that retrofitting trailers with E-track systems reduces annual cargo securement costs by $2,100–$3,800 per vehicle through lower material replacement and fewer damage claims.