Understanding L Track Load Capacity Ratings: WLL, Break Strength, and Real-World Limits

The Working Load Limit, or WLL for short, basically tells us how much weight an L track system can handle safely when things are running normally. To figure this out, engineers take the breaking strength which is basically where the metal gives way and divide it by something called a safety factor. Most often we see factors between 3 to 1 and 5 to 1 in transport situations. Regular static loads just sit there putting pressure on things, but those dynamic forces that come from unexpected stops or sharp turns? They can really crank up the stress levels sometimes triple what we expect. That's why those safety margins matter so much. Let's say we have a track rated at 4,500 pounds before breaking, using our standard 3 to 1 safety ratio means the actual working limit drops down to around 1,500 pounds. Makes sense right? This kind of buffer helps equipment survive all sorts of real world stuff like road vibrations and occasional bumps nobody saw coming.

Static vs. Dynamic Loads: How Working Load Limit (WLL) Is Determined

When vehicles come to sudden stops, the forces acting on cargo can actually be three times greater than its normal weight. That's why Working Load Limit (WLL) ratings are so important for safety. Most industry guidelines call for much bigger safety margins in situations where these extreme forces happen, sometimes as high as five to one. How do manufacturers figure out what these WLL numbers should be? They basically destroy their own products! By breaking multiple samples and seeing at what point they fail, companies calculate average breaking points. Then they apply standard safety factors based on decades of experience. The whole process takes into consideration things like how materials wear down over time, stresses from different angles, and the effects of constant vibrations. All this matters because nobody wants their cargo falling off during transport, especially when lives might be at stake.

Why Published L Track Ratings Range from 1,000 to 4,000 lbs Per Point

Capacity differences arise from three primary factors:

- Material science: 6061-T6 aluminum supports up to 4,000 lbs per anchor point, while 6351 alloy is limited to around 1,500 lbs due to lower tensile strength.

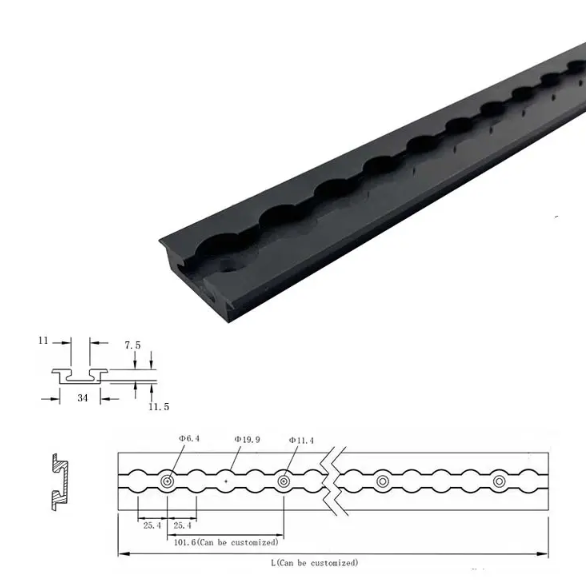

- Design specifications: Heavy-duty tracks feature thicker profiles and reinforced anchor points for enhanced durability.

- Configuration: Double-stud fittings distribute load more effectively, doubling strength compared to single-stud setups. Installation quality significantly influences performance—proper bolting achieves up to 98% of lab-rated capacity, whereas poor mounting can reduce effectiveness by half. Published ratings reflect worst-case dynamic scenarios, not ideal static conditions, ensuring reliability across diverse transport environments.

6351 vs. 6061-T6 Aluminum: Tensile Strength, Corrosion Resistance, and Certification Compliance

The choice of aluminum alloy critically impacts L track performance. 6061-T6, the industry standard, offers 45,000 psi tensile strength—20% higher than 6351—enabling superior load distribution under dynamic stress. Testing confirms that 6061-T6 sustains 4,000 lbs per anchor point with minimal deflection during extreme braking events.

Beyond strength, 6061-T6 provides superior corrosion resistance, lasting three times longer than 6351 in saltwater environments—making it ideal for marine and cold-chain logistics. Its consistent manufacturing meets stringent DOT FMVSS 121 and AS9100 aerospace standards, while 6351’s vulnerability to stress corrosion cracking limits its use in regulated sectors.

According to field reports from the 2024 Heavy Equipment Benchmark Study, equipment running on 6061-T6 aluminum has just 3 load failures for every 100 units, while those using 6351 see around 9 failures in the same number. The difference comes down to how these materials handle stress. The T6 treatment gives better stability when things get shaken up during operation, which stops those tiny cracks from forming in the tracks made from 6351 alloy. Over months and years, these small fractures really add up and weaken performance. That's why serious manufacturers go with 6061-T6 for their tough jobs. When dealing with heavy loads day after day, having material that won't suddenly give way makes all the difference between safe operations and costly breakdowns down the road.

Mounting Surface Integrity, Fastener Spacing, and Load Angle Effects

The actual capacity of installed L tracks tends to drop below what's listed on the spec sheet for several reasons. For starters, the surface where the track gets mounted plays a big role. When tracks are attached to surfaces that aren't solid enough, like rusty old steel or plywood that's started to separate, they just don't transfer weight properly anymore. This makes them more likely to come loose when things get shaken around. Then there's the matter of how far apart the screws go in. Most guidelines say no more than 12 inches between fasteners, but folks sometimes stretch this out. That creates weak spots along the track which eventually bend or warp over time. Lastly, angled forces matter a lot too. Straight down pressure works best, but if something pulls at an angle, especially around 30 degrees off center, the track loses about half its strength potential. This kind of sideways force wears down the hardware faster than anyone wants to deal with.

To maintain performance, reinforce mounting surfaces with steel backing plates and adjust load calculations for directional forces. Overlooking any of these elements compromises the entire system, even if the track itself meets specifications.

Double Lug Studs, Ratchet Straps, and Fitting Compatibility Best Practices

The actual load capacity of an L track system depends on the compatibility and condition of associated hardware. Even high-strength tracks can see effective WLL drop by 50% when paired with mismatched components. Critical considerations include:

- Double Lug vs. Single Stud Fittings Double lug connectors engage multiple anchor points, typically doubling load capacity over single stud designs.

- Ratchet Strap Angle Physics A 45-degree pull increases strap tension compared to vertical loading. Use shorter straps to maintain direct downward force.

- Material Synergy Requirements Combining stainless steel hardware with aluminum tracks risks galvanic corrosion. Match materials to prevent premature degradation.

Independent testing shows improper hardware combinations can reduce system capacity to just 30% of published WLL. To ensure safety:

- Use fittings certified for your track's alloy

- Verify third-party marks such as DOT or TUV

- Replace worn ratchet mechanisms every 18 months

In 83% of overload incidents, failure occurs at the connection point—not the track. Ensuring hardware compatibility is the most effective way to preserve the full load capacity and safety of your L track system.