In the current climate of international trade, securing cargo has become very important. Double stud fittings offer a distinct advantage for safely securing and protecting cargo during transit. This article focuses on how double stud fittings enhance cargo security, their advantages, and their applications.

Understanding Double Stud Fittings

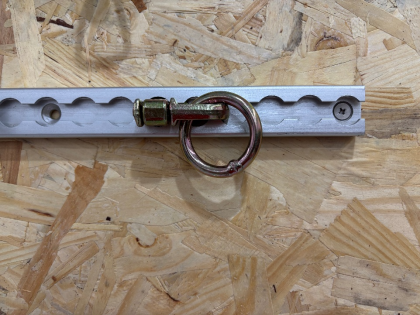

Double stud fittings serve as those little metal anchors that secure cargo inside shipping containers, big rigs, and pretty much any vehicle that moves goods around. What makes them work so well is how they form solid attachment points throughout the container space, keeping everything from sliding around and getting smashed up when things hit bumps on the road. Logistics folks love these fittings not just for how sturdy they are but also because installing and taking them down doesn't take forever. Just snap them into place and voila cargo stays put without needing hours of setup time.

Advantages of Double Stud Fittings

Double stud fittings offer several advantages, though their ability to withstand tough environments without corroding is probably the most valuable feature. These fittings maintain structural integrity even when exposed to extreme conditions, meaning fewer replacements over time. The reason? High quality materials that form the core of these fittings allow them to handle substantial pressure and stress. Manufacturing plants across various industries have started switching to double stud fittings because they simply last longer than alternatives. A chemical processing facility in Texas reported cutting maintenance costs by 35% after making the switch, demonstrating real world value beyond just theoretical benefits.

Applications in Various Industries

The versatility of double stud fittings makes them valuable across multiple sectors including automotive, aerospace work, and building projects. Take cars for instance these fittings help hold parts firmly while vehicles get transported from factory to dealer lots. Without proper securing during transit, components could shift around causing damage that delays delivery times and increases costs. On construction sites things look different but equally important. Workers rely on these fittings when handling big beams or heavy panels because they provide an extra layer of security against accidents. Safety becomes a real concern when dealing with tons of steel and concrete moving around job sites daily.

Enhancing Cargo Security with Innovative Designs

Recent innovations in double studs have further enhanced their security. Locking features and adjustable tension mechanisms allow users to set the fit for different types of cargo, therefore providing more security with customization. These advancements show the commitment of the industry to cargo safety as well as efficiency.

Industry Trends and Future Outlook

Global trade keeps growing at an impressive rate, so naturally the demand for better ways to secure cargo during transport is also on the rise. Smart double stud fittings equipped with tracking tech are currently being developed by several manufacturers. These new devices can actually track cargo conditions as they move across oceans and continents, giving shippers early warnings about problems before they become major headaches. For logistics firms wanting to stay ahead in this cutthroat industry, keeping tabs on these emerging technologies isn't just smart business it's almost essential for survival in today's fast paced shipping environment.

Double stud fittings represent a real game changer for cargo security in recent years. These devices offer something different compared to standard fastening systems because they distribute stress points across multiple attachment points rather than relying on single connection points. Many businesses in the shipping and logistics sector have started incorporating them into their operations, especially those dealing with high value goods that need extra protection during transport. Companies that switch to this system typically see improvements in both efficiency metrics and reduced claims related to damaged shipments. The adaptability factor is what makes them stand out too since they work well with various container sizes and loading configurations without compromising structural integrity.